Adss Apply To High Voltage Power And Have Aramid Yarn All-Dielectric Self-Supporting 12 Core Optic Fiber Cable

Definition:

All-dielectric self-supporting (ADSS) is regarded as one of the best and highly recommended fiber cable. Majority of the professionals refer using this type of fiber optic cable due to its ability to self-support. Currently, the All-dielectric self-supporting (ADSS) is widely used by the electrical utility organisations as a communication medium. Consequently, the users of All-dielectric self-supporting (ADSS) incurs low installation cost since its easily and does not require technical experience to install. In reality, this type of the fiber optic cable is purposely designed to suit the ordinary users who don’t posses technical experience.

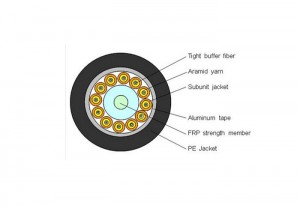

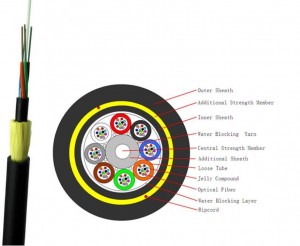

Structure:

In the design of the cable, the internal glass optical fibers are supported with no strain, to maintain low optical loss throughout the life of the cable. The ADSS cable is jacketed to prevent moisture from degrading the fibers. The jacket also protects the polymer strength elements from the effect of solar ultraviolet light.

Using single-mode fibers and light wavelengths of either 1310 or 1530 nanometers, circuits up to 100 km long are possible without repeaters. A single cable can carry as many as 144 fibers.

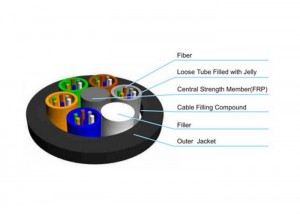

Consequently, ADSS cable is up to 72 optical fibers in jelly-filled loose tube, laid up around a central non-metallic strength member. The cable is water blocked aramid yam reinforced and polyethylene sheathed. Surface printing for the cable includes sequential length marking at one-meter intervals.

Usage:

ADSS is a “dry” water-blocked, loose tube cable that was originally developed from a military lightweight rugged deployable (LRD) field cable. It is now principally used for short span aerial installations—typically on roadside power distribution poles. It is suitable for spans up to 250 m or more, depending upon installation conditions.

Since the ADSS cable is non-metallic, it is ideal for applications near high-voltage power distribution lines for which it has become a standard. This product is also suited to single-point suspension applications such as down mine shafts or any application where the product has to support either a higher load than conventional terrestrial cable or a permanent or varying tensile load that is applied through the outer sheath.

Construction:

250μm Colored Fiber

PBT loose Tube

Tube Filling Compound(Gel)

FRP central strength member

Cable filling compound

PE inner sheath

Aramid yarn

PE outer sheath

Characteristics:

Can be installed without shutting off the power

Excellent AT performance. The maximum inductive at the operating point of AT sheath can reach 25kV

Light weight and small diameter reducing the load caused by ice and wind and the load on towers and backprops

Large span lengths and the largest span is over 800m

Good performance of tensile strength and temperature

The design life span is over 30 years